Fixing a hole in plastic pipe is a common maintenance task that homeowners and professionals encounter when managing plumbing systems. Small holes or cracks in plastic pipe can develop from age, pressure, or physical damage. Learning how to repair damage to plastic pipe prevents water loss and system failure. Even systems using high pressure PVC fittings may develop holes that require repair techniques. The method you choose for fixing a hole in plastic pipe depends on the size and location of damage. Understanding available repair options helps you select the most appropriate solution for your plastic pipe. This guide explains various methods for fixing holes in plastic pipe effectively and reliably.

Assessing the Damage to Your Plastic Pipe

Proper assessment determines the best approach to fix holes in your plastic pipe. Locate the hole carefully by inspecting where water is leaking from plastic pipe. Determine the size of the hole ranging from small pinhole leaks to larger cracks. Check whether the hole affects a straight section of plastic pipe or a fitting connection. Examine the area around the hole for other damage or cracks in plastic pipe. Assess water pressure in your system to understand how quickly plastic pipe is losing water. Understanding the extent of damage helps select appropriate repair methods for plastic pipe. Thorough inspection prevents choosing inadequate solutions to fix holes in plastic pipe.

Temporary Patches for Emergency Plastic Pipe Repairs

Temporary patches provide immediate relief when plastic pipe develops holes unexpectedly. Self-fusing silicone tape can wrap around plastic pipe to seal small holes temporarily. Apply self-fusing silicone tape tightly around the area with the hole in plastic pipe. Stretch the tape as you wrap to maximize adhesion on damaged plastic pipe. This temporary repair on plastic pipe typically holds for hours or days. Waterproof epoxy putty can fill small holes in plastic pipe as a temporary measure. Mold epoxy putty to seal the hole area on plastic pipe. Allow epoxy to cure according to product instructions before water pressure testing. These temporary solutions buy time while planning permanent repairs to plastic pipe.

Hose Clamp and Repair Tape Method

Repair tape combined with hose clamps provides a semi-permanent fix for plastic pipe holes. Clean and dry the area around the hole in the plastic pipe thoroughly. Wrap waterproof repair tape tightly around the plastic pipe covering the hole completely. Position a hose clamp over the repair tape on the plastic pipe. Tighten the hose clamp firmly to compress the repair tape against the plastic pipe. This method works well for small to medium holes in plastic pipe. The repair remains effective for extended periods when properly installed on plastic pipe. Replace the repair tape if it begins deteriorating on plastic pipe. Hose clamp repairs allow continued use of plastic pipe while planning permanent solutions.

Rubber Patch Kits for Plastic Pipe

Specialized rubber patch kits provide durable repairs for holes in plastic pipe. These kits include rubber patches designed specifically for plastic pipe repair. Clean the area around the hole thoroughly before applying rubber patches to plastic pipe. Apply waterproof adhesive from the kit to both the plastic pipe and the rubber patch. Press the rubber patch firmly over the hole in the plastic pipe. Clamp the patch in place while the adhesive cures on the plastic pipe. Allow complete curing time according to kit instructions before pressurizing plastic pipe. Rubber patch repairs work well for medium-sized holes in plastic pipe. Quality kits designed for plastic pipe hold up well under pressure and temperature variations.

Pipe Repair Epoxy for Permanent Solutions

Pipe repair epoxy offers a more permanent solution for fixing holes in plastic pipe. Clean and dry the damaged area on the plastic pipe thoroughly. Mix two-part epoxy according to manufacturer directions for plastic pipe repair. Apply epoxy directly into and around the hole in the plastic pipe. Work epoxy into the damaged area ensuring complete coverage on plastic pipe. Allow epoxy to cure fully according to product specifications before pressurizing plastic pipe. Epoxy repair creates a strong, permanent bond when properly applied to plastic pipe. Large holes require more epoxy application when repairing plastic pipe. Test the repair by turning on water pressure gradually to the plastic pipe. Epoxy repairs on plastic pipe typically last for years under normal conditions.

Section Cutting and Replacement Method

Severe damage may require cutting out the damaged section of plastic pipe. Turn off the water supply and drain the system before working with plastic pipe. Cut out the damaged section of plastic pipe using a hacksaw or pipe cutter. Cut straight across the plastic pipe to ensure proper fitting alignment. Install new plastic pipe sections using appropriate fittings. Connect replacement plastic pipe sections with new or existing fittings rated for your system. Ensure all connections are tight and properly supported. This method provides the most reliable solution for extensive damage to plastic pipe. Complete system replacement is sometimes more cost-effective than extensive repairs to plastic pipe.

Preventive Measures to Protect Plastic Pipe

Preventing holes in plastic pipe avoids the need for repairs altogether. Install plastic pipe protection in areas prone to physical damage. Bury plastic pipe at appropriate depths to prevent external damage. Maintain proper water pressure to avoid stressing plastic pipe connections. Inspect plastic pipe regularly for early signs of deterioration. Protect plastic pipe from UV exposure in outdoor installations. Monitor water chemistry as certain conditions accelerate plastic pipe degradation. Proper maintenance prevents many common plastic pipe problems. Preventive care extends the lifespan of plastic pipe systems. Regular inspection catches minor issues before they require major repairs to plastic pipe.

When to Replace Rather Than Repair Plastic Pipe

Extensive damage may warrant replacing plastic pipe rather than attempting repairs. Multiple holes or cracks indicate the plastic pipe is reaching end of service life. Age-related deterioration of plastic pipe suggests replacement is prudent. Repairs to plastic pipe using high pressure PVC fittings require careful evaluation. Systems experiencing repeated failures need comprehensive replacement. Cost comparison may show replacement more economical than continued repair efforts. Professional assessment helps determine whether repair or replacement suits your plastic pipe. Systems nearing the end of their expected service life should be replaced proactively. New plastic pipe offers improved performance compared to aging systems needing frequent repairs.

Conclusion

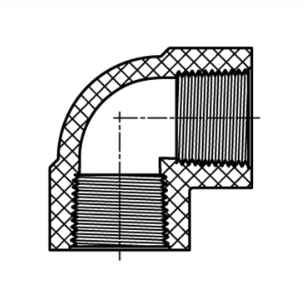

Fixing holes in plastic pipe ranges from temporary patches to permanent epoxy repairs or complete section replacement depending on damage severity. Understanding available repair methods helps you choose appropriate solutions for your plastic pipe damage. To sustain its flawless plastic injection-molded product line and sales network, LESSO America manufactures and delivers high-quality plastic fittings with the latest injection mold tools and technology through distribution centers from coast to coast. LESSO America provides quality plastic pipe and high pressure PVC fittings along with replacement components to support your repair and maintenance needs.